BlueScope Lysaght’s Design and Construction business has played a key role in the construction of the first large scale water desalination plant on Australia’s eastern seaboard.

The Gold Coast Desalination Project was initiated by Gold Coast City Council and is now owned by SureSmart Water whose sole shareholder is the Queensland Government.

Located on a six hectare former landfill site at Tugun, adjacent to the Coolangatta Airport, the new plant can supply up to 125 megalitres a day of pure drinking water to South East Queensland.

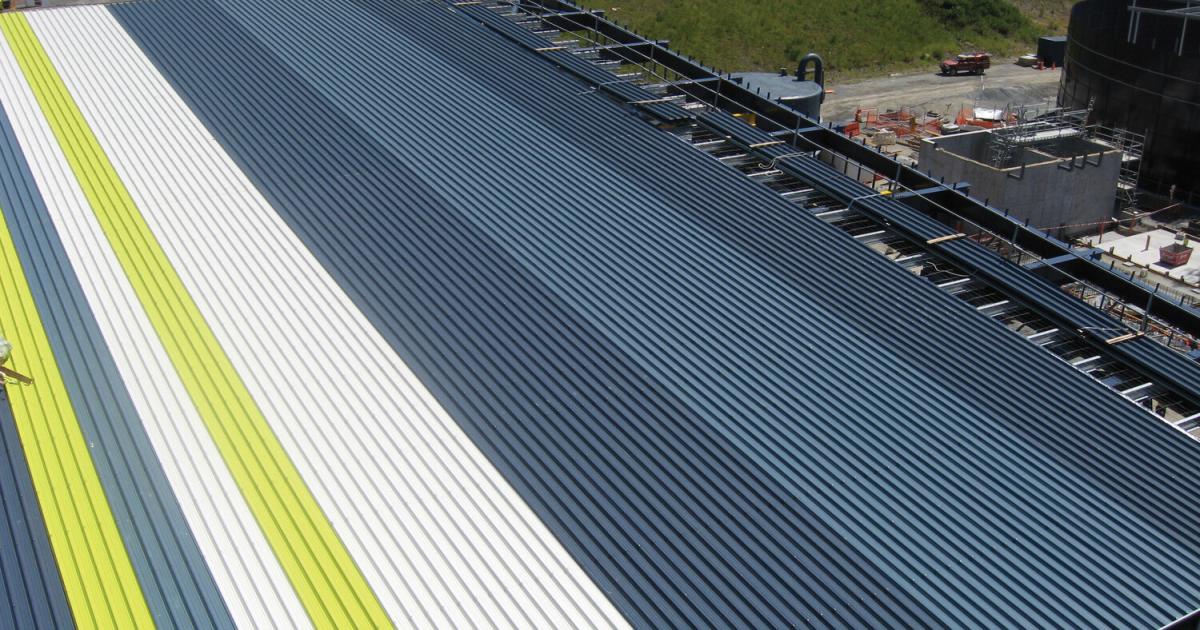

BlueScope Lysaght worked closely with the Gold Coast Desalination Alliance (GCDA) partners and the facility owner to supply, install and warrant an attractive, durable cladding system for ten buildings which will be constantly exposed to salt laden air in an industrial setting.

The GCD Alliance is an alliance of John Holland, Veolia Water, Sinclair Knight Merz and Cardno.

Chris Johnsson, BlueScope Lysaght’s national product manager for Permalite® worked with the project’s engineers from the outset to develop an appropriate solution for purlins, bridging, cladding and flashing.

He worked with GCD Alliance member Sinclair Knight Merz to develop shapes of structural members as part of the cladding package and provided advice on where conventional galvanized purlins could be used.

Permalite® products are the Lysaght® solution for aggressive environments where durability, style, economy and good looks are all important.

They are made from marine grade aluminium, roll formed to produce high performance cladding or extruded to produce purlins with an exceptional combination of strength and light weight.

BlueScope Lysaght’s design and construction team was originally contracted to supply and install purlins and cladding for the Gold Coast plant’s pre-treatment and reverse osmosis buildings and a large pumphouse.

This was subsequently expanded to include administration, main sub-station, sludge dewatering, chemical storage, chemical switch building, potable water pump station and gatehouse buildings on the site.

Because of its extensive experience with building products for aggressive environments, BlueScope Lysaght was able to reduce construction costs for the GCDA by using conventional Z and C purlins with a Z450 zinc coating in appropriate situations.

As a result of its total confidence in the product and the quality of its fixing, BlueScope Lysaght’s Design and Construction business was able to offer unprecedented warranties.

The company’s Permalite® solution ensures cost containment and long-term functionality for the plant with the backing of a 26 year warranty on installation and 40 years on materials.

Installation of the cladding for the $1.2 billion desalination plant began in December 2007 and involved a project manager and a crew of up to 20, regularly resized to suit the changing demands of the building program.

The Tugun facility buildings have been clad in more than 35,000 square metres of Permalite® wall and roof sheeting in V-RIB® and LT7® profiles.

BlueScope Lysaght is also providing a Permalite® cladding solution for key buildings at the Sydney Desalination Plant which is now under construction.